In the last year of looking for CAM (toolpath) software, I don't recall seeing any with support for MAC OS. I suppose you could run a Virtual Machine and run it under that but, I would proceed cautiously there as most will require pretty tight control over the graphics card -and that's a weak area for most VM software. Cnc for mac free download. Dxf2gcode DXF2GCODE is a tool for converting 2D (dxf, pdf, ps) drawings to CNC machine compatible GCode. The Carveco ™ software range is the trusted CAD modelling and CNC machining solution to a multitude of industries worldwide. The easy-to-use, yet immensely powerful, tools included in Carveco software give sign-makers, woodworkers, engravers, jewellers (and countless other creatives) the freedom to design and manufacture high-quality 2D or 3D products from their artwork, faster than they. Tutorial help about. RhinoCAM is a CAM Software plug-in that runs completely inside of Rhinoceros 5.0 & 6.0 (Windows only).RhinoCAM marries the power of Rhino’s freeform modeling with the legendary CAM functionality of VisualCAM to bring you a product of unrivaled capability.

Computer Numerical Control, or CNC programming, software creates program codes and instructions, which are used to run a CNC linked tool. Instructions reach the tool or machine via a computer. More often than not, CNC software works to enhance or automate the manufacturing process.

In specific, its programming software helps machines understand function and design. The design for what the machine creates is Computer-Aided Design (CAD) software. The design is then translated into a language the machine understands by a Computer-Aided (CAM) software program.

Computer Numerical Control is not new. In fact, it has existed since the early 1970s when it was called Numerical Control or NC programming and flexibility. While this all sounds complicated, there are a few things to know about CNC software. Below we're giving some information on the best CNC software for beginners.

What does CNC software do?

Working in place of or in tandem with other manufacturing processes, CNC software improves automation. It makes the products of manufacturing more accurate and consistent. As technology continues to change, these automation processes are vital in helping businesses to scale and produce more cost-effective products for customers.

CNC Software Applications

CNC has an effect on every facet of manufacturing. CNC machines replace or work with existing manufacturing processes.

First, operators use Computer-Aided Design software to create a design or utilize the templates provided on the CAD software.

This is a blueprint or drawing. Using CNC software, the “blueprints” for what you want your machine to produce are created. If you can envision a product, CNC machines can create it.

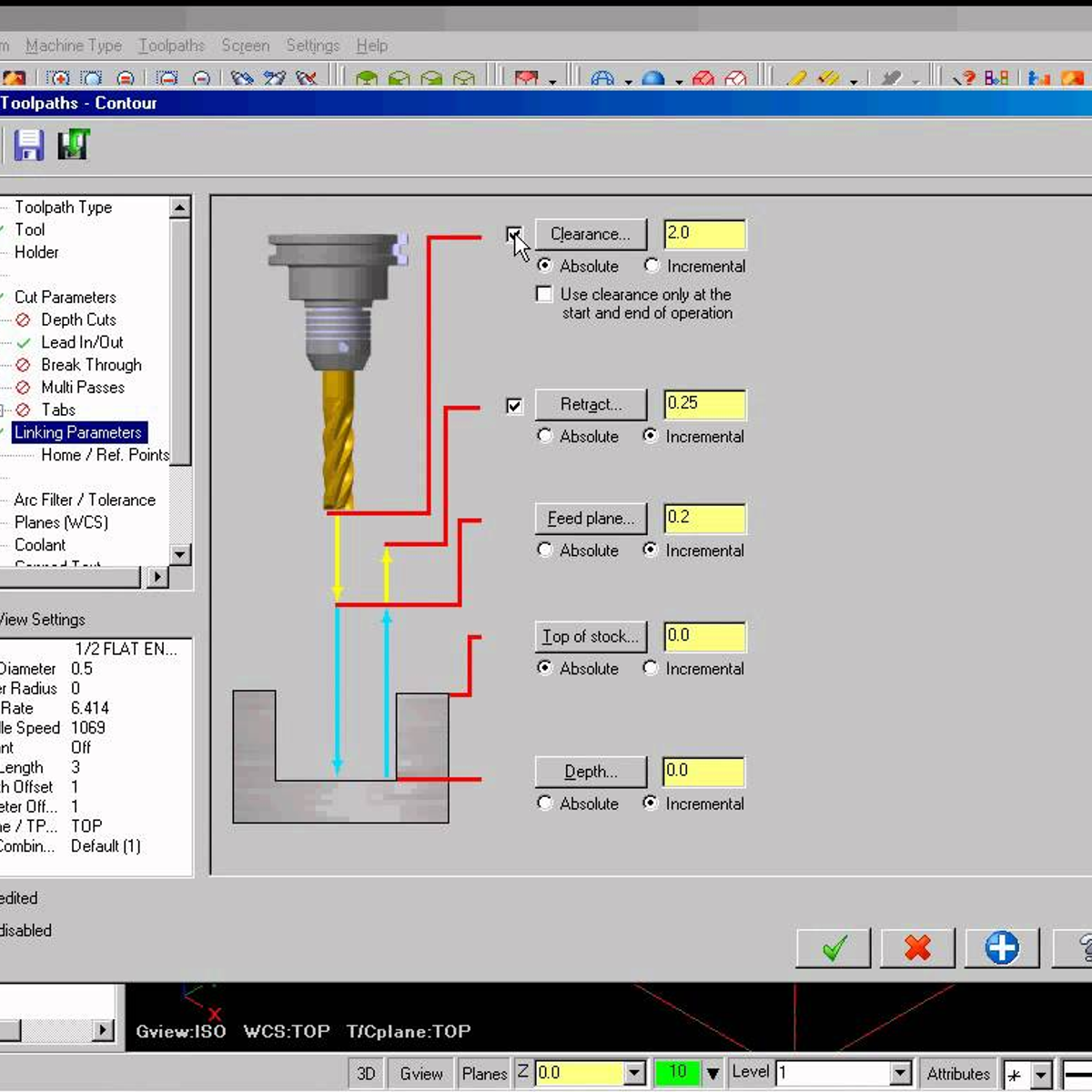

CAM software takes the CAD drawing file and creates a g-code. This is what your CNC machine requires to run its passes. The machine needs information about what work needs to be done. The machine also needs direction about feed and machine speed. The speed and feed calculator provides this input. Also built into your CNC software is a controller.

In a nutshell, CNC takes the data created by CAD. CAM puts it into a language your machines can understand and creates a g-code. Essentially, this means typing commands and having specialized machines execute it immediately.

So what is the final product? CNC machinists use machinery controlled by CNC software to produce parts and tools. These can be fabricated from a variety of materials including wood, metals, and plastics. The precision machinery performs tasks like slicing, cutting, grinding, milling, and drilling into and around material.

Besides parts and specialized pieces, CNC machines can produce signs, etchings, engravings, and unique products to suit clients’ special needs.

What are the basics beginners need to know?

Tools

The best CNC software for beginners allows users to know how to use the hardware on which the CNC software is loaded. They need an understanding of the machines which receive their cd.

Programming

It is imperative that beginners are able to use CNC software. They need to be able to create designs. Further, they need to be able to use CNC software to convert the designs they have accessed in the templates on the software or created using the software to g-code. These are sent to machines telling them what to do.

What do beginners need?

First, beginners need to find CAD software they can use comfortably and grow with. This is the first of the three software products they need. Because it is the first and the one they will be using the most, this one must be user-friendly. It can take a long time to master CAD programs. Without a positive experience with this software, the entire CNC software program is doomed.

There is no single CAD software program for everyone. Each operator has different skills and needs.

New CAD designers need a minimum of two weeks to become familiar with CAD software. During that time, they need software technicians who will provide knowledge and support.

Before using a CNC Machine, beginners need to spend time gaining expertise with CAD software.

In service

Skilled technicians of the CNC software company generally provide training to those new users of CNC machines. Hands on experience, is the only true way to learn.

Competency in math, science, and computer skills are necessary. Knowledge of how the complex machines and tools work in the field is a bonus.

Support

As CNC technicians become proficient in creating designs and sending them to their machines the CNC software company needs to be available to provide support when there are problems. They also need to encourage operators to become more adept at using the software by providing workshops, webinars, and other opportunities for the expansion of their learning and skills.

Software with Room to Grow

Ideally, the best CNC software for beginners allows users to start simply and access additional parts of the software as their expertise and the demands of the job increase.

Why Use SAi EnRoute CNC Software?

EnRoute software is a user-friendly and easy to learn software with toolpath capabilities. The software provides clear direction for CNC routers, CNC lasers, CNC plasma and CNC waterjet cutters.

If you require everyday cutting, nested-based production and/or creative design applications, then SAi EnRoute CNC software can provide it.

EnRoute offers round the clock support for new CNC software users as they grow with the program.

EnRoute CNC software is affordable and cost effective. Our subscription model allows client flexibility. You can buy what you need and add to the payment package or change it to meet your needs as they evolve.

SAi EnRoute for Beginners

New users can access the beginning templates they need to get started. As they become more sophisticated in their use of the software, the program has additional options and programs they can access. EnRoute software provides an endless array of creative choices that will support users from novice to highly experienced and competent.

In order to help beginners, SAi CNC software includes a basic software package with room for future growth.

- SAi EnRoute CNC software adjusts feeds and speeds to what the machine can handle.

- Written tips are included.

- There is a user-friendly cheat sheet. It allows the beginner to tailor things like working speed, longer tool life, better finish.

- SAi CNC software includes support information for getting started and a glossary of useful terms.

Updates to SAi's CNC Software, EnRoute 6

The newest SAi CNC software version is EnRoute 6.1 and one of the best CNC software for beginners. This software builds on the established capabilities of SAi's popular EnRoute CAD and CAM software. These programs deliver intuitive, user-friendly, creative tools, and accurate tool pathing. The machines thus receive commands to carve, cut, slice, or engrave on various materials.

EnRoute software facilitates integration with three-axis CNC machines. These machines provide woodworking, CNC sign making as well as CNC manufacturing and fabrication products.

Version 6.1 has over fifty modifications and comprises many time-saving features. These combine to make designing faster and more productive.

The newest CNC program by EnRoute has a fully-equipped interface. There are enhanced nesting options and new nesting capabilities.

Relief creation and editing has new ways to offset and distortion tools. New toolpaths increase creativity and deliver precise results.

Contact us to learn more about our CNC software that is ideal for novice users.

Simplified 2D CAD/CAM

Combine the power of 2D sketching and machining, with 3D simulation to see your designs come to life! Download ms office for mac 2011.

We wrote this software from scratch to give our customers the quickest path from idea to part.

Carbide Create is downloaded software that's run from your own machine, it’s not cloud software that can be insecure and unavailable.

Best of all, it's free for everyone, not just Carbide 3D customers.Get Carbide Create for Free

Build: 474 Released: 7-20-2020

Build: 474 Released: 7-20-2020

Carbide Create is Cross-Platform.. without the Cloud

Cnc Cam For Mac

Carbide Create is downloadable software that runs on Windows and OSX computers. In fact, it's the only cross-platform CAD/CAM software available that doesn't depend on 'The Cloud'. (Let's face it, if you're looking for CAD/CAM for the Mac, your options are limited)

Why are we against the cloud? Because it locks you into a vendor- their availability and their willingness to continue providing the software.

If we've done our job right, you'll come to depend on Carbide Create and we don't want you to think that we're holding you hostage. Download the software and keep it. Use it where ever and however you want.

We don't want to limit you.

Carbide Create is a Full-Featured 2D Design Program

Create Basic Shapes

This is not a shock, but Carbide Create lets you quickly create basic shapes.

Splines

Create smooth, organic shapes with bezier spline tools.

Background Images

Load a background image so you have a reference for your design. Whether you're looking to just make sure the parts are in proportion or you need to carfully trace an image, this will be a huge feature for you.

Alignment

If you need to make parts that fit perfectly, the alignment tools in Carbide Create will help you put all of the sections of the design in the correct locations.

Booleans

Booleans are an incredibly powerful way to combine simple shapes into more complex ones. Carbide Create supports unions, intersections, and subtractions.

Offsets

You can select a vector and create another vector that's offset to the inside or outside from the original one.

Text

You can create text vectors from any font on your computer. You can treat it like anything else you drew from scratch so all of the tools work the same way for text that they do for anything else.

Import DXF and SVG

If you need to start your design from another program or file, you can load SVG and DXF files directly into Carbide Create.

If your design is already done and you just need to create toolpaths, not problem- load it in and start machining.

Why is Carbide Create Free?

We make great desktop CNC machines and CNC Routers but the machines themselves are only part of the equation- they need software to go with them.

We created Carbide Create to help our users get started quickly without searching for software. We kept getting questions from people who weren't our customers but wanted to use Carbide Create. We finally said, 'Why not?'

So here's the deal- use Carbide Create and enjoy it. (Please send us photos of what you make with it.) If you decide to upgrade your CNC, consider one of ours. If you wow a friend and they'd like to get into CNC, please send them our way.

Carbide Create has all of the machining tools you need

V-Carving

Create detailed 3D carvings without the time and effort of 3D modelling

Pockets / Contours

Pockets and contours are the basic operations in any machining job. Carbide Create has them.

Engraving

Engrave text, or any other design, directly into your design.

Tool Library

Keep a library of all of your favorite cutting tools ready to go.

Cnc Cam Software For Mac

Speeds and Feeds

Let Carbide Create estimate the best speeds for cutting your parts.

Simulation

See what you're going to get before you even walk up to your machine.

Get Carbide Create

Enter your email below and we'll send you the download links and documentation to get started with Carbide Create.

Don't worry, every email has an unsubscribe link if you never want to hear from us again.

Need 3D CAM Software?

Carbide Create is a great way to go for 2D and 2.5D CAD/CAM. If you need 3D toolpaths, or you need to work with a full 3D CAD program, then we'd recommend MeshCAM.

We include MeshCAM with all of our Nomad Pro Desktop CNC machines and it's the easiest way to machine 3D parts.